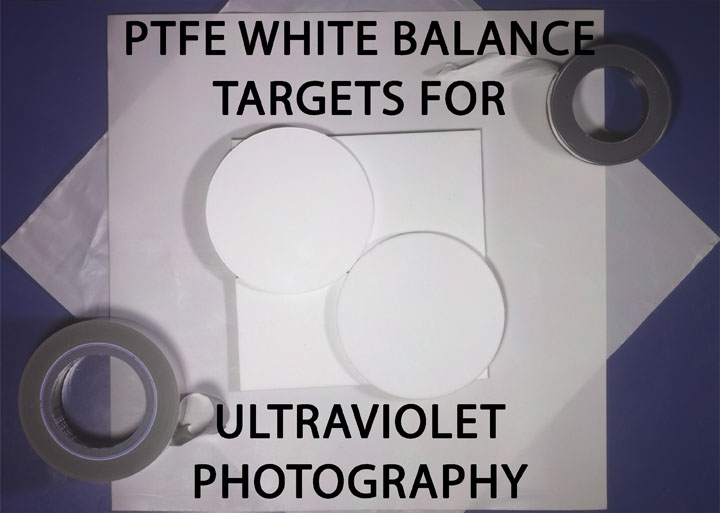

PTFE makes for a good white balance target as it is neutral in ultraviolet, visible, and infrared light. In this post I'm going to be looking at how the thickness of the PTFE and the choice of backing material behind thin PTFE affects the result in UV. Can we use a cheap thin piece of PTFE with some other material behind it to create a suitable white balance target, or do we need to use a more expensive thicker piece of PTFE?

A video version of this blog post is available here if you prefer: PTFE White balance targets for Ultraviolet Photography.

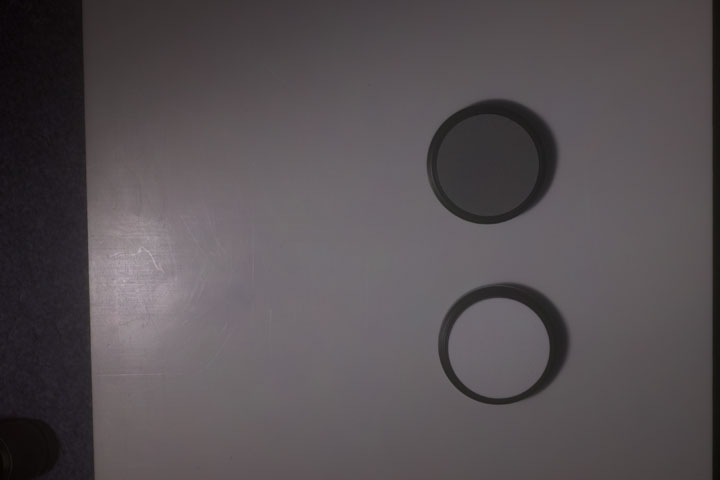

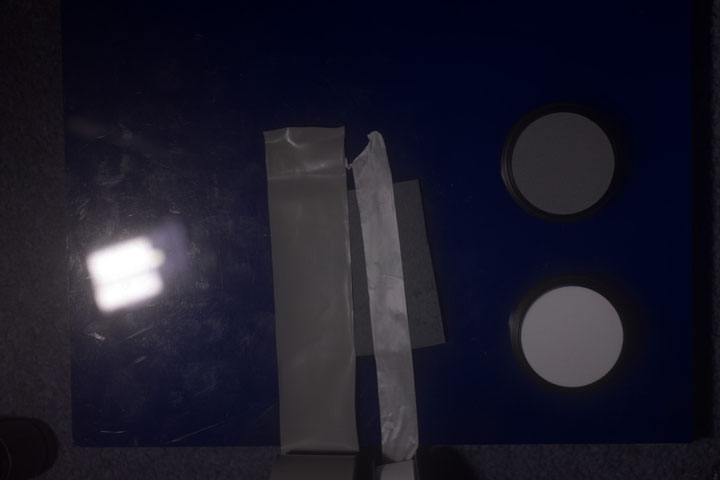

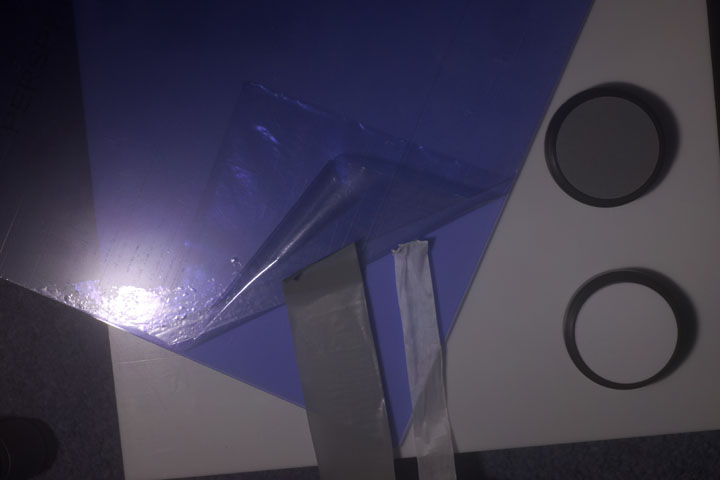

The test setup was a larger sheet of PTFE onto which the test subjects were placed. On the right-hand side we have Labsphere Spectralon 20% reflectance and 99% reflectance standards. Images were shot using a full spectrum modified Canon R5 with the non-N 80mm f/5.6 EL-Nikkor and a Baader U filter placed in a drop-in adapter behind the lens. Images were converted in Adobe Camera RAW using a custom profile and white balanced on the Spectralon 20% reflectance standard (with the same white balance being applied to all images).

We can then look at how neutral the target appears by checking its RGB values. It should be noted that even with a custom profile, ACR is not ideal for UV images, as with the tint maxxed out green we are still not perfectly white balanced. But so long as the G value is within 2-3 points of the R and B values (which should be about equal) when checking our test targets we can say it is a good result.

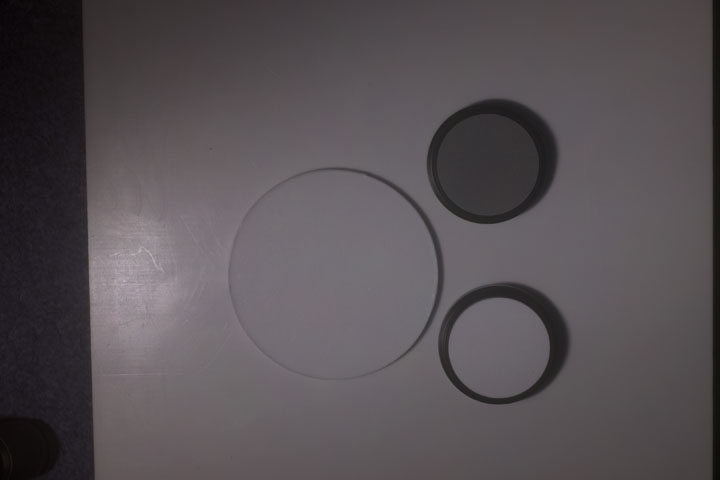

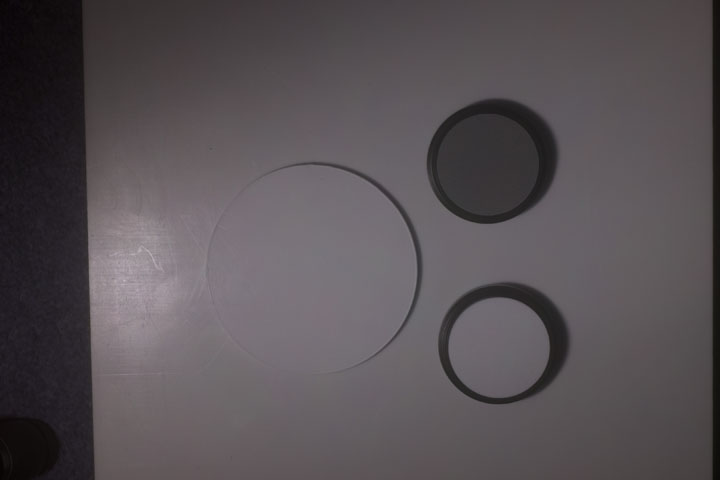

3mm thick PTFE

This first test is with a 3mm thick disc of PTFE in the centre, which gives a good result.

A 3mm thick disc of ePTFE gives a very similar result.

And a 3mm thick 10cm square piece of PTFE gives a similar result as well. The PTFE background piece and these 3mm pieces were all purchased from different sellers, so at least from my small sample size I don't really see any difference in the neutrality between them.

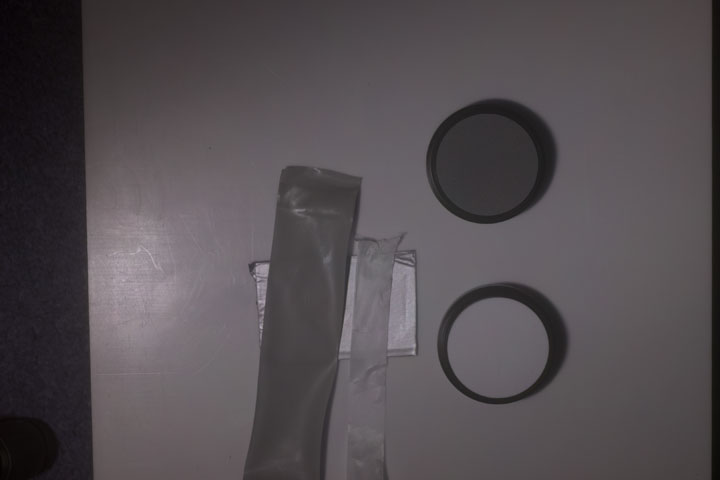

Thin PTFE with foil side of Tetra Pak as backing

This image shows a piece of Tetra pak with the foil side up and a piece of adhesive backed grey PTFE plumbers tape on the left of it and non-adhesive white PTFE plumbers tape on the right of it. Both tapes are pretty thin, especially the white tape. They both look pretty good.

Similarly, 0.1mm thick and 0.25mm thick PTFE sheet on top of the Tetra Pak looks good.

Thin PTFE with brown cardboard as backing

For this image I swapped out the background for some frosted acrylic, which appears blue in UV. This shows the two tapes again, but this time on a piece of brown cardboard. The card has a very slight blue tint, but is pretty neutral in UV and so does not seem to negatively affect the tapes.

Then checking the 0.1mm and 0.25mm thick PTFE sheets over the same brown cardboard, they both give a similarly good result.

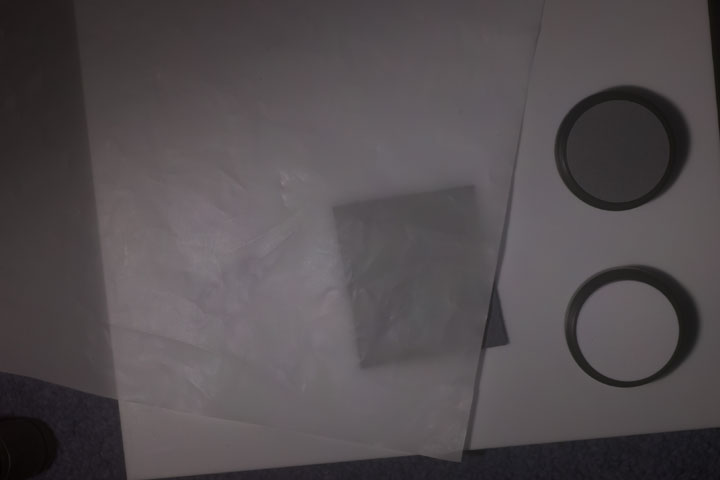

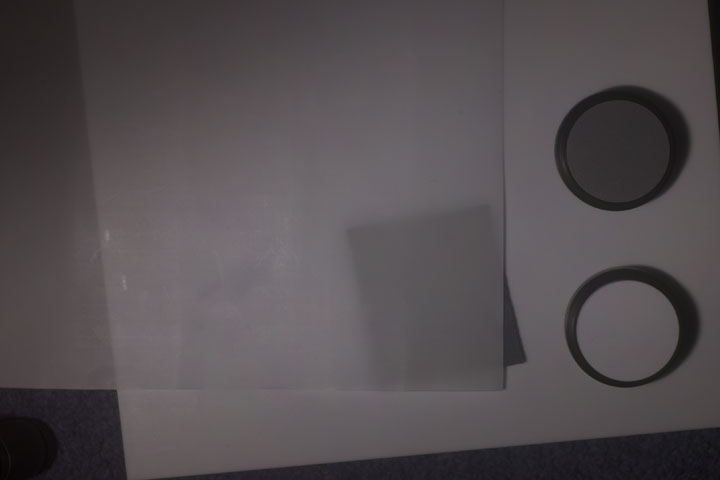

Thin PTFE with 2mm thick clear Perspex as backing

Next looking at the tapes on a 2mm thick piece of clear perspex. Although the perspex is clear in visible light, it has a blue colouration in a white balanced UV photo. To the eye the tapes look neutral, but we can see when checking the RGB values that there is a slight blue colouration coming through the tape from the perspex.

Neither the 0.1mm or 0.25mm thick PTFE sheets are thick enough to prevent the blue showing through from the perspex below. So we can say that perspex with PTFE tape or thin sheet stuck to it or wrapped round it would not make a good white balance target for UV.

Thin PTFE with 1mm thick transparent acrylic as backing

1mm thick transparent acrylic is much the same, the blue of the acrylic shows through the thin PTFE making it unsuitable for use as a white balance target. Perspex is just a brand-name for Acrylic, so unsuprising we see little difference here.

Thin PTFE with 0.5mm thick PVC as backing

This is the PTFE tape on a piece of clear 0.5mm thick PVC, though I had not removed the protective film from the PVC. The thicker Grey tape looks good, but the thin white tape has a slight blue tint.

If we compare on the opal perspex background we see a similar result. This also shows that at least with the protective film still in place, the PVC is not completely transparent in UV but is more a slightly translucent very light blue. (I will be doing a test looking for UV transparent plastics in the future).

The thin PTFE sheets still allow through the slight blue tint of the PVC below.

Conclusion

So standard white PTFE in 3mm+ thickness seems the best target since it is neutral across UV-IR.

Thin PTFE sheet over the foil side of Tetra Pak card would also make a good target plus be thinner. However, most glue is not UV transparent and so to stick the two together you'd either need to use expensive UV transparent optical adhesive, or just glue it round the edges.

The issue with grey PTFE tape on Tetra pak backing is that the grey tape is not neutral in visible light. It has a slight brown / orange colouration (at least the tape that I bought does):

PTFE in 3mm thickness, while more expensive than thinner sheets, is still pretty cheap for a small piece. I have cut the 3mm thick 100mm square sheet into a credit card sized piece - it just needed a few strokes with a stanley knife to cut through it. Then I put a strip of the grey PTFE tape on it I can use for UV WB without exposure adjustment (hopefully). The 3mm thickness is too thick to fit in a standard credit card slot in my wallet, but I can fit it in the other side.

It's not ideal to keep the WB target in a wallet like this, as it will get dirt and oils on it that could affect how neutral it is. But for me it is more convenient to have something in my wallet I'm not going to forget to bring with me, and the accuracy should hopefully still be good enough for my purposes.

Leave a Reply